2026 Best Geomembrane Welding Machine for Your Projects?

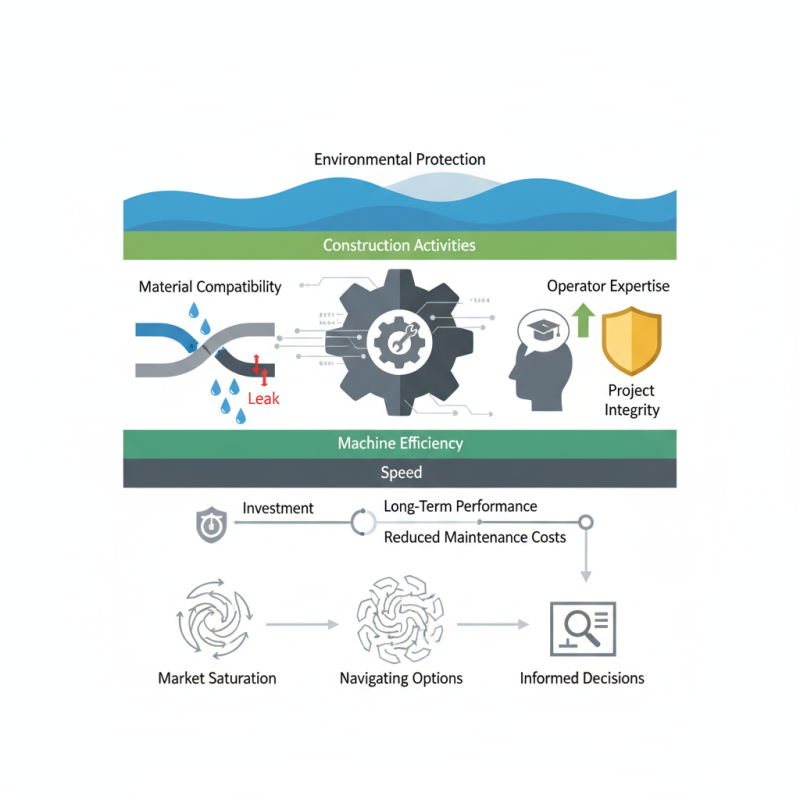

In the world of construction and environmental protection, the use of geomembrane welding machines has become essential. These machines are crucial for creating durable, waterproof barriers in landfills, reservoirs, and other projects. According to market reports, the geomembrane industry is projected to grow significantly, driven by heightened environmental regulations and increasing construction activities.

Choosing the right geomembrane welding machine can be challenging. Factors include machine efficiency, speed, and material compatibility. Data shows that improper welding can lead to leaks, which can compromise project integrity. Inadequate training with these machines may lead to costly errors. Companies often overlook the importance of operator expertise in achieving optimal results.

Investing in a high-quality geomembrane welding machine is important. While many brands offer various features, assessing their long-term performance is crucial. The right choice can enhance project efficiency and reduce maintenance costs. Nevertheless, the market is saturated, and navigating these options can be daunting. Operators must reflect on past projects to make informed decisions.

Overview of Geomembrane Welding Machines

Geomembrane welding machines play a crucial role in a variety of construction and environmental projects. These machines are designed to create strong, durable bonds between geomembrane materials. They are commonly used in landfills, ponds, and other containment systems. The welding process ensures that there are minimal leaks, providing an effective barrier against contaminants.

Selecting the right welding machine is vital. Factors like operating temperature, welding speed, and material compatibility must be considered. Operators often face challenges, such as inconsistent heat distribution or improper alignment. These issues can compromise the quality of the weld. It’s essential for users to undergo proper training to handle the machines effectively.

Regular maintenance is key to ensuring optimal performance. Neglecting machine care can lead to failures during critical projects. Operators should routinely check for wear and tear. Keeping the nozzles and turbines in good condition helps maintain precision in the welding process. Investing in knowledge and skills will ultimately yield better results in any geomembrane project.

Key Features to Consider in a Geomembrane Welding Machine

When selecting a geomembrane welding machine, certain key features are crucial for project success. Look for robust temperature control. Optimal temperature prevents material damage and ensures strong seams. Reported data indicates that improper heat settings can result in up to 30% weaker welds. This highlights the importance of precision in any welding operation.

Another vital feature is the speed of the machine. Faster operation can boost productivity significantly. However, rushing might compromise quality. Choose a machine that balances speed and effectiveness. A report from industry experts shows that projects with efficient machines saw a 25% reduction in overall costs, thanks to less rework.

Tips: Always conduct a test weld to check settings. This extra step can save time and materials. Additionally, consider the weight of the machine. A heavy machine may seem more durable but can be a hassle to transport. Moreover, ensure the machine suits various materials and thicknesses. Flexibility is key in diverse project environments.

Types of Geomembrane Welding Technologies

When it comes to geomembrane welding technologies, choosing the right method is crucial. There are several techniques available, such as hot wedge welding, extrusion welding, and radio frequency welding. Each method has unique benefits and challenges.

Comparison of Leading Brands in 2026

When choosing a geomembrane welding machine in 2026, the market offers a variety of options. Each machine comes with unique features tailored to different projects. Power, durability, and ease of use are essential considerations. Some machines are lightweight, making them portable and convenient for onsite tasks. However, lighter machines may sacrifice strength.

One should also evaluate the welding speed. Faster machines can save time but may compromise seam integrity. Always seek well-reviewed performance metrics to understand if speed aligns with quality.

Tips: Always read user feedback. Practical insights can reveal issues not covered in specs. Also, consider local service availability. Support can be invaluable if unexpected failures occur. Remember, while low cost might seem enticing, hesitation is wise here. A cheaper machine can often lead to greater long-term expenses due to repairs or replacements.

Tips for Selecting the Right Welding Machine for Your Project

When choosing a geomembrane welding machine for your project, it's vital to consider several key factors. According to industry reports, over 40% of project failures are attributed to improper equipment selection. Assessing the specific application and material type is crucial. Different geomembranes have varying thicknesses and properties, which means your welding machine must accommodate those differences effectively.

Another critical factor is the machine's temperature control capabilities. Studies show that machines with precise temperature regulation can improve weld integrity. A fluctuating temperature can lead to weak seams. The right machine should also have adjustable speed settings. This flexibility allows for better adaptation to project demands.

Portability is another consideration. A lightweight machine can be advantageous for site mobility. However, balance this with power and efficiency. Investing in a robust machine may increase upfront costs, but it could pay off in durability and performance. Often, project managers overlook the importance of ongoing maintenance. A well-maintained machine can last 20% longer than one that is neglected. Reflecting on these points will ensure that your selection process aligns with project needs and long-term goals.