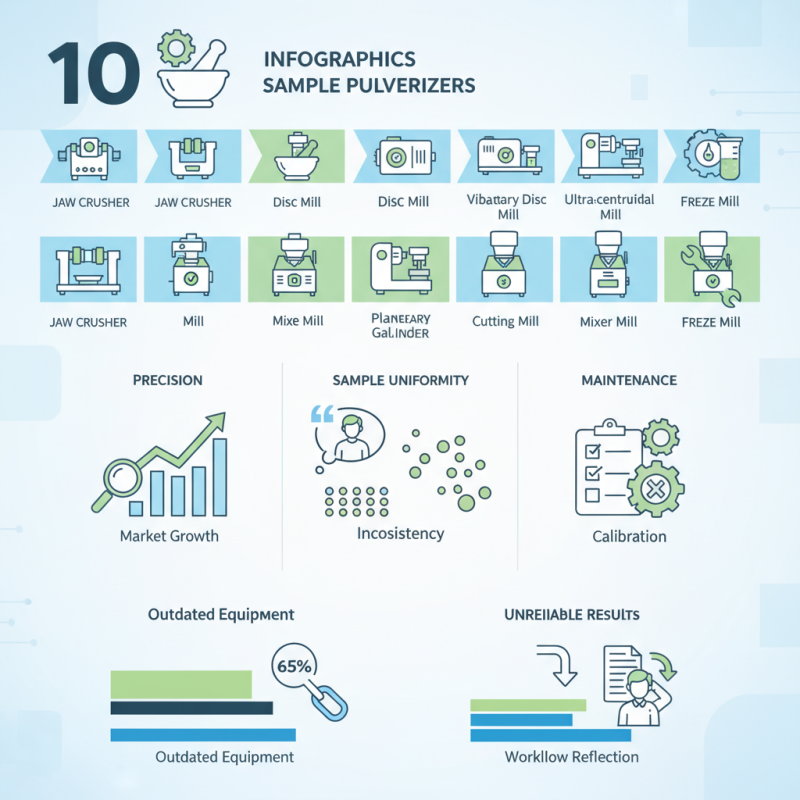

Top 10 Laboratory Sample Pulverizers for Optimal Results?

In the world of scientific analysis, precision is key. The laboratory sample pulverizer plays a vital role in preparing samples for accurate testing. According to a report by ResearchAndMarkets, the global market for laboratory instruments is projected to grow significantly, emphasizing the need for efficient pulverization techniques. Industry expert Dr. Emily Carter once stated, "Choosing the right laboratory sample pulverizer fundamentally impacts the quality of test results." Her insight underscores the importance of equipment selection.

laboratory sample pulverizers come in various forms, each designed for specific applications. The choice of pulverizer affects the granule size and uniformity of the sample. A recent survey indicates that nearly 65% of labs struggle with inconsistent sample preparation due to outdated equipment. This inconsistency can lead to unreliable test outcomes, which is a concerning trend for researchers and quality control professionals.

While it's easy to focus on equipment quality, many laboratories overlook proper maintenance. Regular checks and calibration are essential for optimal performance. Without these practices, even the best laboratory sample pulverizers may underperform. This often leads to a cycle of dissatisfaction and error in test results, necessitating reflection on laboratory workflows.

Overview of Laboratory Sample Pulverizers and Their Importance

Laboratory sample pulverizers play a vital role in scientific research. They help in preparing samples for analysis by reducing materials to a fine powder. This process is essential for achieving accurate results in various experiments. Without proper pulverization, samples may not provide reliable data. The quality of a sample can significantly affect the outcome of scientific studies.

Choosing the right pulverizer can be challenging. Each type has unique features and applications. Some may be ideal for hard materials, while others work better on softer substances. It is crucial to match the pulverizer to the specific requirements of the sample. Over-reliance on one type may lead to inconsistencies in results. Researchers often need to reflect on their choices. What works for one project may not suit another.

Efficiency is key in laboratories, but it is not always easy to achieve. The wrong settings can lead to uneven particle sizes. This variability can compromise the integrity of the sample. Sometimes, a quick fix is tempting, but rushing may hinder the quality of work. Understanding the limitations of each pulverizer is essential for achieving optimal results in sample preparation.

Key Features to Consider When Choosing a Pulverizer

When selecting a laboratory sample pulverizer, several key features should guide your choice. Power output is vital. A strong motor can efficiently crush various materials. Fine adjustments in speed help control particle size. Ideally, look for an adjustable pulverizer for enhanced precision.

Durability is another crucial factor. A robust design can withstand daily wear and tear. Materials should be high-quality to prevent premature breakdowns. Consider the ease of cleaning, as residue can affect future tests.

The size of the pulverizer plays a role as well. Compact models save space but may limit input sizes. Think about your workload. Will it handle large samples? Remember, it’s not just about price. Investing in quality may save costs in the long run. Some features might not seem essential initially. However, they can increase efficiency and improve results.

Top 10 Laboratory Sample Pulverizers

This bar chart represents the average particle size reduction efficiency of different types of laboratory pulverizers. The data reflects optimal performance based on various types of materials processed.

Top 10 Laboratory Sample Pulverizers Reviewed

Laboratory sample pulverizers play a crucial role in materials analysis. These devices reduce sample sizes to achieve optimal particle distribution and enhance testing accuracy. According to a recent industry report, effective pulverization can improve data reliability by up to 30%. This highlights the importance of selecting the right equipment for your laboratory needs.

When reviewing pulverizers, consider the material compatibility. Not all pulverizers handle every sample type effectively. Some units may struggle with fibrous or hard materials, leading to inconsistent granulations. A study indicated that improper pulverization can result in sample variation, impacting results in critical analyses. You might reflect on your current pulverization methods and whether they meet your standards.

Moreover, ease of use and maintenance cannot be overlooked. Complex machinery often leads to user errors. This can affect the uniformity of samples produced. A survey of laboratory technicians revealed that 40% find maintenance challenging. Regular upkeep is essential for accurate results. As you explore your options, think critically about how each pulverizer aligns with your laboratory workflow. The right choice can significantly enhance efficiency and the quality of your analytical processes.

Comparative Analysis of Pulverizer Performance and Results

In the world of laboratory sample preparation, the choice of pulverizer can significantly impact results. Each pulverizer presents unique characteristics that can affect particle size distribution and homogeneity. A comparative analysis reveals that some machines excel in speed, producing fine powders quickly. However, a faster operation sometimes compromises uniformity.

Consider the materials being processed. Certain pulverizers perform better with softer samples but may struggle with harder materials. Their design plays a crucial role in their efficacy. For example, blenders may create heat, which alters sample properties. A user must be mindful of these aspects. It’s essential to recognize that no single pulverizer suits every application.

Some units demonstrate durability and longevity but are limited in their grinding capabilities. Reflections on performance highlight the importance of user preference and sample requirements. It’s prudent to test different machines before settling on a particular model. This approach can lead to more optimal results while also addressing potential shortcomings. Ultimately, a thoughtful selection can enhance workflow in any laboratory.

Maintenance Tips for Optimal Performance of Pulverizers

When it comes to pulverizers, proper maintenance is crucial for achieving optimal results. Regular cleaning is essential. Dust and residue buildup can impact performance. According to industry reports, improper maintenance can decrease efficiency by up to 30%. Keeping components clean ensures smoother operations and more accurate results.

Lubrication is another area of focus. Regular checks on bearings and moving parts are necessary. A neglected machine can lead to increased wear and tear. Data shows that well-lubricated machines last significantly longer, with some extending life by 50%. Not paying attention to lubrication could lead to costly repairs or replacements.

Balancing is a subtle yet significant aspect. An unbalanced pulverizer can vibrate excessively. This not only affects the accuracy of sample sizes but also strains the machine. A report highlighted that unbalanced equipment can result in a 15% drop in throughput. Regularly checking for balance can prevent hidden issues and ensure consistent performance. Neglecting these maintenance tips may lead to unforeseen downtime or suboptimal results.

Top 10 Laboratory Sample Pulverizers for Optimal Results

| Pulverizer Model | Max RPM | Material Type | Sample Capacity (g) | Maintenance Frequency (weeks) |

|---|---|---|---|---|

| Model A | 3000 | Metal | 500 | 4 |

| Model B | 2500 | Glass | 300 | 5 |

| Model C | 2000 | Ceramic | 100 | 6 |

| Model D | 3500 | Plastic | 800 | 3 |

| Model E | 2800 | Organic | 600 | 4 |

| Model F | 2200 | Minerals | 700 | 6 |

| Model G | 3400 | Composite | 750 | 2 |

| Model H | 2600 | Fiberglass | 400 | 5 |

| Model I | 3000 | Alloys | 550 | 4 |

| Model J | 3100 | Sulfur | 500 | 3 |